Decorative chromium

is a thin chromium deposit applied to a metallic or plastic substrate in order to impart particular surface properties:

- Bright appearance;

- corrosionresistance;

- Wear resistance;

- Scratch resistance.

Decorative chromium is thinner than hard chromium. Additionally decorative chromium depositions have micro-discontinuity (micro-porous, micro-crack) structure in contrast to hard chromium, which is normally crack-free.

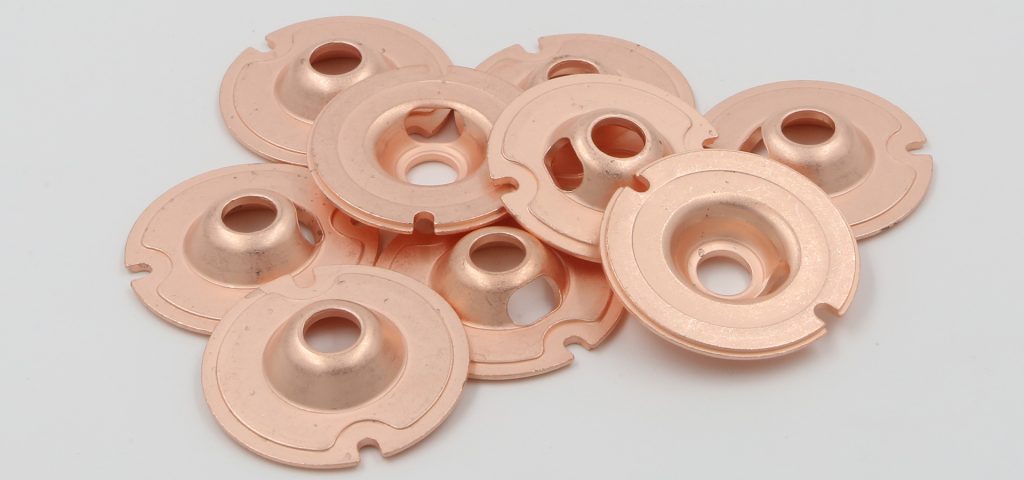

Typical applications of decorative chromium Electroplating:

- automotive parts (interior and exterior);

- plumbing fixtures;

- metal furniture;

- hand tools;

- Bicycles.

Advantages of trivalent chromium over hexavalent chromium decorative plating process:

- Lower toxicity.Hexavalent chromium solutions are carcinogenic, oxidizing and more acidic (more corrosive) than trivalent chromium.

- Lower chromium concentration. Chromium content in trivalent solutions is about 1/5 of that in hexavalent solutions.

- Higher productivity.

- Simpler process control.

- Less sensitive to the rectifier ripple.

- No treatments are required for formation micro-porous/micro-crack structure. Trivalent chromium deposits are micro-porous. Hexavalent chromium should be pre- or post-treated to form micro-crack structure.

- Lower drag-out. Trivalent chromium solutions have lower viscosity therefore the parts transfers less electrolyte to the rinse baths.

- Higher throwing power.

- Less expensive waste treatment and ventilation systems.

Disadvantages of trivalent chromium over hexavalent chromium decorative plating process:

- Trivalent plating solutions are more sensitive to contaminations. More frequent bath analysis is required.

- Trivalent solution components are more expensive.

- Limited deposit thickness.

- Deposit color does not meet some requirements.

At present, our company have both Hexavalent chrome and Trivalent chrome.